| Sign In | Join Free | My adobecards.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My adobecards.com |

|

Brand Name : xinzheng

Model Number : Sanitary Tube

Certification : ISO,SGS,ISO & SGS,ISO/CE/SGS

Place of Origin : CHINA

MOQ : 1 PCS

Price : 1-2USD / kg

Payment Terms : L/C, D/P, T/T, Western Union, MoneyGram

Supply Ability : 4000 MT PER week

Delivery Time : 5-25 Days

Packaging Details : Standard seaworthy export package

Standard : ASME ,AISI,ASTM, EN, ISO

seamless Tube : Up To 652 mm OD

wall thickness : 0.5mm to 200 mm

Trade Name : 316L stainless steel

Technique : Cold drawn , Hot rolled

Application : offshore platform, oil, gas, boiler

Type : Seamless , Welded

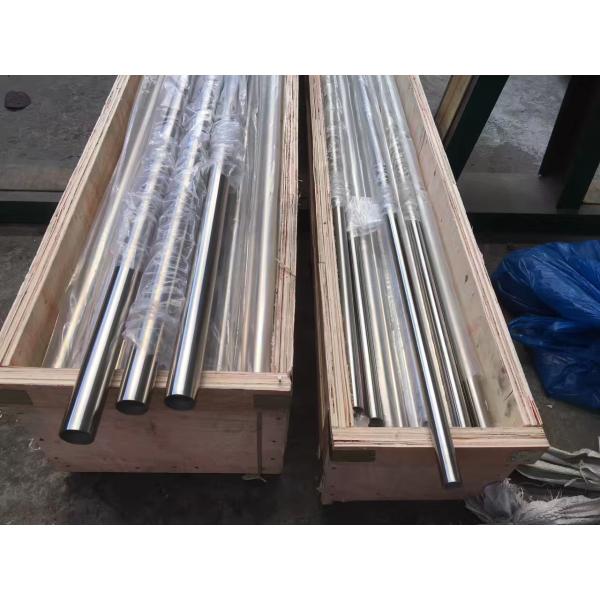

Finish : Polished , Mill finished

Welding line type : Seamless

316L Stainless Steel Pipe is an extra-low carbon version of the 316 steel alloy. Cost wise Stainless Steel 316L Pipe is similar to 316, and is durable, corrosion resistant, and a good choice for high-stress situations. Compared to chromium-nickel austenitic stainless steels, TP316L Tube offers higher creep, stress to rupture and tensile strength at elevated temperatures. TP316L Stainless Steel Pipe is in high demand for a project that requires a lot of welding. TP316L Pipe are commonly used in chemical and petrochemical industry, food processing, pharmaceutical equipment, potable water, wastewater treatment, marine applications and architectural applications.

| Material | ALLOY 316L • UNS S31603 • WNR 1.4404 |

| ALLOY 316LN • UNS S31653 • WNR 1.4429 | |

| ALLOY 316LVM • UNS S31673 • WNR 1.4441 | |

| Stainless Steel 316L Tube Standards | ASTM A213, ASTM A249, ASTM A269, ASME SA213, ASME SA249, ASME SA269, EN 10216-5 TC1 / TC2, PED 97/23/EC, AD 2000, NACE MR0175/ISO 15156 |

| Typical Manufacturing Specifications | 316L Stainless Steel Pipe |

| ASME B36.19 | |

| ASTM A213 | |

| ASME SA213 | |

| ASTM A269 | |

| ASTM A312 | |

| ASTM A632 | |

| NFA 49-117 | |

| BS 10216 | |

| and as per customer specifications. | |

| 316LN Stainless Steel Pipe | |

| ASTM F138 | |

| ASTM F2181 | |

| and as per customer specifications. | |

| 316LVM Stainless Steel Pipe | |

| ASTM F138 | |

| ASTM F2181 | |

| and as per customer specifications. | |

| Stainless Steel 316L Seamless Tube Size | 3.35 mm OD To 101.6 mm OD |

| Stainless Steel 316L Welded Tube Size | 6.35 mm OD To 152 mm OD |

| Swg & Bwg | 10 Swg., 12 Swg., 14 Swg., 16 Swg., 18 Swg., 20 Swg. |

| Stainless Steel 316L Pipe wall thickness | 0.020" –0.220", (special wall thicknesses available) |

| SS 316L tube Length | Single Random, Double Random, Standard & Cut length |

| 316L Stainless Steel Tube Finish | Polished, AP (Annealed & Pickled), BA (Bright & Annealed), MF |

| SS 316L Pipe Schedule | SCH5, SCH10, SCH10S, SCH20, SCH30, SCH40, SCH40S, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS |

| Form | Round, Square, Hollow, Rectangular, Hydraulic, Coiled, Straight Pipes, “U” Shape, Pan Cake Coils etc. |

| Stainless Steel 316L Tube Type | Seamless, ERW, EFW, Welded, Fabricated |

| Electropolished | (EP) Electropolished for Ultra High Purity Systems |

| Non-Electropolished | (BA) Bright Annealed or (AP) Annealed & Pickled for High-Purity, (CFOS) Cleaned for Oxygen Grade Service or Corrosive Systems |

| I.D. Surface Finish Options | 5, 7 & 10 µin. Ra |

| JIS | 8A to 250A |

| Tolerances | In accordance with: ASTM: A269 & A632, JIS: G 3459 |

| 316L stainless steel Pipe End | Plain End, Beveled End, Treaded, Ends are suitable for orbital welding |

| 316L stainless steel Pipe Application | Oil Tube, Gas Tube, Fluid Tube, Boiler and Heatexchanger |

| Value Added Service | Draw & Expansion as per required Size & Length, Polish (Electro & Commercial) Annealed & Pickled Bending, Machining Etc. |

| Specialize in | Stainless Steel 316L Capillary Tube & Other Odd Size |

| Stainless Steel 316L Heat Exchanger & Condenser Tubes | |

| Stainless Steel 316L Hydraulic Pipe with OD up to 50.8 mm (2.0 in.) are delivered in bright annealed condition | |

| Stainless Steel 316L hydraulic tube with OD larger than 50.8 mm are supplied in the annealed and pickled condition, Or in polished condition | |

| 316L stainless steel Pipe Test Certificate | Manufacturer Test Certificate according to EN 10204 3.1 B |

| Laboratory Test Certificate from Govt. Approved Lab. | |

| Under Third Party Inspection | |

| We can also cut, thread, and groove Stainless Steel 316L Tubes to meet your specifications | |

other Stainless steel Tubing Dimension ranges :

| Product Name | Executive Standard | Dimension | Steel Code / Steel Grade |

| Industrial Pipes | ASTM A312, A358, A778, JIS G3459 | OD: 1/4"~40" | TP304, TP304L, TP316L, SUS304TP |

| WT: SCH5S~SCH80S | |||

| Tubes for Boiler and Heat-Exchanger, General Service Tubing | ASTM A249, A269, JIS G3463 | OD: 15.9~139.8mm | TP304, TP304L, TP316L, SUS304TB |

| WT: 1.6~5.0mm | |||

| Mechanical and Structural Tubes | ASTM A554, JIS G3446 | OD: 7.9~152.4mm | MT304, MT304L, MT316L, MT430 Grade 201, 202 as per mill's STD SUS304 |

| WT: 0.5~6.5mm | |||

| Square Tubes | ASTM A554 | OD: 12.7x12.7~150x150mm | MT304, MT304L, MT316L, MT430 Grade 201, 202 as per mill's STD |

| WT: 0.7~6.5mm | |||

| Rectangular Tubes | ASTM A554 | OD: 10x20~100x200mm | MT304, MT304L, MT316L, MT430 Grade 201, 202 as per mill's STD |

| WT: 0.7~6.5mm | |||

| Sanitary Tubing | ASTM A270 | OD: 25.4~165.2mm | TP304, TP304L, TP316L, SUS304TBS |

| JIS G3447 | WT: 0.8~3.05mm | ||

| Large Gauge Pipes for Ordinary Piping | JIS G3448 | OD: 15.88~318.5mm | SUS304TPD |

| WT: 0.8~3.0mm | |||

| Large Diameter Pipes | JIS G3468 | OD: 14"~40" | SUS304TPY |

| WT: SCH5S~SCH40S |

ASTM A312 TP316L material properties are that it has a Tensile Strength of 485 (MPa) min. ASTM A312 TP316L has a minimum Yield Strength of 170 MPa. The Elongation at Break of ASTM A312 TP316L is 40. The Rockwell B Hardness of ASTM A312 TP316L is 95. ASTM A312 TP316L has a Brinell Hardness of 217. The Melting Range of ASTM A312 TP316L is 1390–1440 °C (2450–2630 °F). ASTM A312 TP316L has an Electrical Resistivity of 74 Microhm-cm at 20 °C (29.1 Microhm-in at 68 °F).

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | |

| 316L Stainless Steel | min. | – | – | – | – | – | 16.0 | 2.0-3.0 | 10.0 | – |

| max. | 0.035 | 2.0 | 0.75 | 0.045 | 0.030 | 18.0 | 14.0 | – | ||

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min | Hardness | |

| Rockwell B (HR B) max | Brinell (HB) max | ||||

| 316L Stainless Steel | 485 | 170 | 40 | 95 | 217 |

| Grade | Density (kg/m3) | Elastic Modulus (GPa) | Mean Coefficient of Thermal Expansion (m/m/0C) | Thermal Conductivity (W/m.K) | Specific Heat 0-1000C (J/kg.K) | Electrical Resistivity (n.m) | |||

| 0-1000C | 0-3150C | 0-5380C | at 1000C | at 5000C | |||||

| 316L Stainless Steel | 8000 | 193 | 15.9 | 16.2 | 17.5 | 16.3 | 21.5 | 500 | 740 |

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Stainless Steel 316L | 1.4404 / 1.4435 | S31603 | SUS 316L | 316S11 / 316S13 | 03Ch17N14M3 / 03Ch17N14M2 | Z3CND17‐11‐02 / Z3CND18‐14‐03 | X2CrNiMo17-12-2 / X2CrNiMo18-14-3 |

| Alloy | Temper | Tensile Strength KSI | Yield Strength KSI | Minimum Elongation in 2" (%) | Rockwell Hardness* |

|---|---|---|---|---|---|

| Stainless Steel 316L | Annealed Half Hard Full Hard | 100 max. 110-140 140 min. | 30-50 70-110 110 min. | 35 15 6 | B 95 max. B 95 - C 26 C 24 min. |

| Types | Out diameter | Sizes | Length |

|---|---|---|---|

| NB Sizes (in stock) | .0035” ~ 8” | 1/8", 1/4", 3/8", 1/2", 5/8", 3/4", 1", 1.25", 1.5", 2", 2.5", 3", 4", 5", 6" | Cut to length |

| Stainless Steel 316L Seamless Tube (Custom Sizes) | 6.35 OD To 101.6 mm OD | As per requirement | Cut to length |

| Stainless Steel 316L Welded Tube (ERW Tube) (in Stock + Custom Sizes) | 6.35 OD To 152 mm OD | As per requirement | Cut to length |

| Surface Finish | Internal Surface(ID) | Exterbal Surface(OD) | |||

| Roughness Average(RA) | Roughness Average(RA) | ||||

| μ inch | μm | μ inch | μm | ||

| AP | Annealed & Pickled | Not defined | Not defined | 40 or Not defined | 1.0 or Not defined |

| BA | Beight Annealed | 40,32,25,20 | 1.0,0.8,0.6,0.5 | 32 | 0.8 |

| MP | Mechanical Polish | 40,32,25,20 | 1.0,0.8,0.6,0.5 | 32 | 0.8 |

| EP | Electro Polish | 15,10,7,5 | 0.38,0.25,0.20;0.13 | 32 | 0.8 |

FAQ

Q: Would you provide samples For free?

A: Yes . with on stock specification We provide samples For Free . Freight charge collect

Q: What information should i provide to source for the right products ?

A: Material grade, width, thickness, coating and Purchase quantity , Expected lead time ,etc

Q: What are the shipping ports?

A: Under normal circumstances, we ship from Shanghai, Tianjin, Qingdao, Ningbo ports, you can choose other ports according to your needs.

Q: About product prices?

A: Prices vary from period to period due to cyclical changes in the price of raw materials.

Q: How long does your delivery time take?

A: In general, our delivery time is within 5-45 days, and may be delayed if the demand is extremely large or special circumstances occur.

Q: Can I visit your location?

A: Of course, we welcome customers from all over the world to visit our factory. However, some of the plants are not open to the public.

Q: Does the product have quality inspection before loading?

A: Of course, all our products are strictly tested for quality before packaging, and unqualified products will be destroyed.

Q: How to pack the products?

A: The inner layer has a waterproof paper outer layer with iron packaging and is fixed with a fumigation wooden pallet. It can effectively protect products from corrosion during ocean transportation.

Q: What is your working time?

A: In general, our online service time is Beijing time: 8:00-22:00, after 22:00, we will reply to your inquiry during the next working day.

Sanitary tubing ,sanitary tube , sanitary pipe , dairy tubing ,dairy pipe ,dairy tubing , water tubing ,

water tube , water piping , food grade tubing , Aerospace tubes ,ANSI/ASME pipe ,ASME/ASTM welded pipe

Bimetallic tubes ,Boiler tubes,Capillary tubes,Chemical injection lines ,Coiled tubing,Composite tubes ; Condenser tubes ; Control lines ; Downhole casing ; Ethylene furnace tubes ; Evaporator tubes ; Finned tubes ; Fittings ; Flanges ; Flowline piping ; Furnace tubes ; GDI and CNG fuel system tubes ; Heat exchanger tubes ; Phosphoric acid production ; Urea production ; High-pressure tubes ; High-temperature tubes; Hollow bar ; Hydraulic tubing ; Instrumentation tubing ; ISO/EN tubes ; Lance tubes ; Mechanical tubing

Medical tubes ;Muffle tubes ; Nitric acid tubes ; Nuclear fuel tubes ; Nuclear steam generator tubing

Precision tubes ; Production tubing (OCTG) ; Recuperator tubes ; Reheater tubes ; Riser tubes ; Scrubber tubes ; Steam generator tubes ; Stripper tubes; Subsea tubes ; Superheater tubes ; Thermocouple tubes

Titanium tubes ; Umbilical tubes ; Zirconium tubes, Nickel alloy tube ,Nickel alloy tubing , super aolly Tube , Superalloy tubing , Copper tube , copper tubing . ANSI/ASME pipe ASME/ASTM welded pipe Bimetallic tubes Boiler tubes Capillary tubes Chemical injection lines Coiled tubing Composite tubes Condenser tubes Control lines Downhole casing Ethylene furnace tubes Evaporator tubes Finned tubes Fittings Flanges Flowline piping Furnace tubes GDI and CNG fuel system tubes Heat exchanger tubes High-pressure tubes High-temperature tubes Hollow bar Hydraulic tubing Instrumentation tubing ISO/EN tubes Lance tubes Laying head pipe Mechanical tubing Medical tubes Muffle tubes Nitric acid tubes Nuclear fuel tubes Nuclear steam generator tubing Precision tubes Production tubing (OCTG) Recuperator tubes Reheater tubes Riser tubes Scrubber tubes Steam generator tubes Stripper tubes Subsea tubes Superheater tubes Thermocouple tubes Titanium tubes Umbilical tubes Zirconium tubes

|

|

A312 Stainless Steel Seamless Pipes TP316L For Heat Exchanger Seawater Images |